188_257-198_980-271_Side Curtain Kits_MG TC, TD, TF_Instructions.doc

Created on 11/18/2005 4:15:00 PM Created by grantm

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

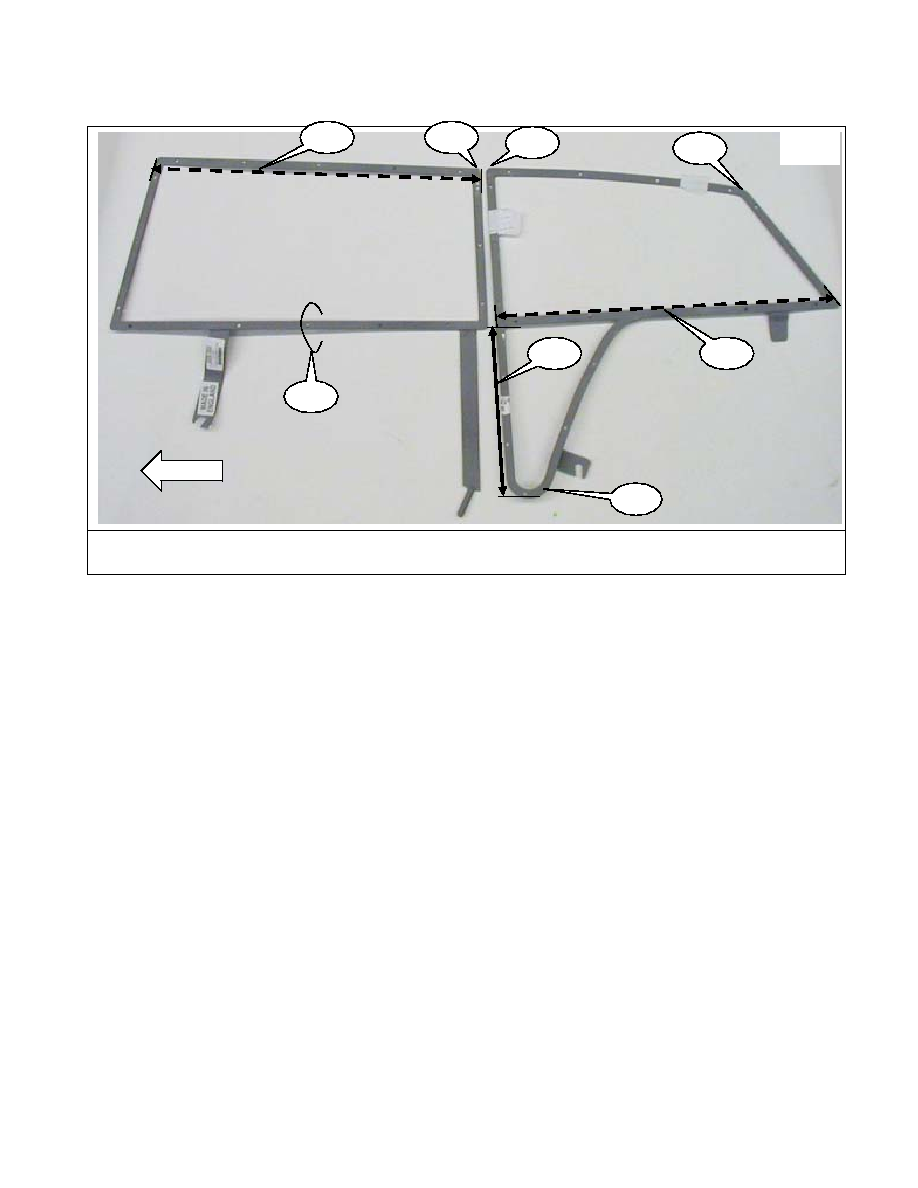

253-100 LH front, 253-300 LH Rear Side Curtain Frames

Things to look for

The upper front corner of the rear frame is almost a 90 degree angle (1C)

The upper rear corner of the rear frame is angular, not rounded (1D)

The dropped section of the rear s/c frame (1E) is gently rounded.

The rear TC s/c frame is the only one with this rounded point.

Lay a tape measure along the inside edge of the upper horizontal piece.

Measure the length of the steel piece from outside to outside edge.

It’ should be 19 ¾ inches long. (about 21 inches would be TD, and over 22 is a TF)

If 1E is rounded as shown you can skip the measurements below

To confirm the identity of the rear frames:

Lay a tape measure along the inside edge of the lower horizontal piece.

Measure the length of the steel piece from outside to outside edge.

It’ should be 20 inches long. (about 17 ¾ to 18 1/4 inches would be TD, and less than 17 is a TF)

The metal strap used to make the lower pieces of the TC frames is flat (1G).

The material used to make the TD frames is actually like a small piece of angle iron.

The depth of the dropped point (1H) is 9 7/8 inches.