MGTF SEAT RECOVERING . . . 1

by John Crawley

alittlemoreink@hotmail.com

11/06/2007

The Moss

instructions for covering the TF seats are a bit on the sparse

side. To begin with they suggest that it is a complex process

that should not be undertaken by and amateur. I found that using

just a few upholstery techniques a fairly decent job can be

done

by one who is willing to give it a try. I have illustrated the

process with

photographs

(pix) and will try to keep the description to a minimum. This is

not a step by step instruction manual but might help you over

the rough spots. If you need help

just drop me and e-mail. Dismantle

the seats noting how the original or re-upholstery was done

A

professional staple remover helps but is not necessary

It is best

to have the seat rails cad plated

If the seat rail screws will not come out it is because the captive nuts

have broken

loose from the

plywood, simply drill the head off.

The “Horse hair”

stuffing inside will be covered with “mouse nest” cotton

The “Horse hair”

stuffing will have sunk backwards particularly at the top.

Retain

the original cotton and felt stuffing that surrounds the

perimeter if possible.

The seat

bottom my be salvageable or may have to be remade.

Getting the exact measurements is

essential.

Use the rails to guide the drill.

Captive nuts are inserted.

I painted the finished wood to help

preserve it.

Tools for re-upholstering: very good scissors, tack

hammer (grind the surfaces flat not

convex), spray glue, box

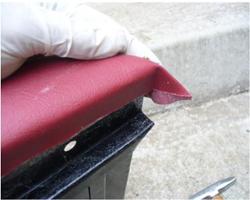

of tax and the first piece of vinyl.

trim the vinyl to shape

of the top edge of the seat frame but leave at least 2 in. to

fold

over.

MGTF SEAT RECOVERING . . . 2

Almost ready to fold over.

Notch

the vinyl to fit around the front edge of the seat back and fold

it over.

Remember that the spray glue must be on both

surfaces and should be allowed to

almost dry before sticking. Rolling or gentle hammering

with a wooden mallet will

ensure a good stick were

required.

The bottom

edge is folded under the seat bottom frame.

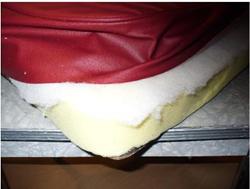

Now for the seat cushion the upholsters padding can be

split to prevent too thick of a

padded look.

I used Moss foam and found that it fit just fine. A

single split layer of filler covers the

top of the foam.

(Addendum: In use I found the Moss foam too soft. On my next

one I will try to get

denser foam or salvage the old foam

with high density foam inserts stuffed into the

original foam’s

cast hollows . . . I saw this as a tip somewhere and can nor

remember

where so can not give credits for it.)

the foam must be trimmed a bit with a bread knife to fit the wooden seat

bottom.

The wooden frame is

place over the trimmed foam.

28. The cover appears to be too small but the foam can be

compressed and stuffed

inside.

Now pull the material over the bottom

of the seat and tack but do not drive the tacks

home yet.

Now for the seat back This is the hardest

part. I used a 18 in square of foam and

covered it with upholsters fill split in

1/2

A bit of the foam must be trimmed to fit the “dog leg” on the

inside of the seat back.

The old black vinyl seat shows the typical slanted top that seats

develop with time.. the red seat show the squared off effect

that was original. This and getting the top of the seat wrinkle

free is the biggest problem of doing the seats.

MGTF SEAT RECOVERING . . . 3

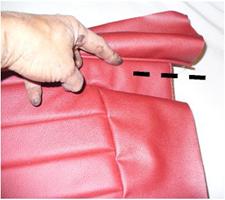

Both sides have the seam cut.. On the original upholstery

the leather was cut on the

dotted line but I was afraid to do this as there is then

no way of going back and

relieving the seam worked perfectly.

It just did

not fit. I had to cut the seam that is at the top side of the

inner seat back. Since it is impossible to machine sew this

again I replaced the stitching through the top piece of leather

only by hand, following the original machine holes. I then let

the top piece of leather

overlap the bottom piece. This approach gave me a wrinkle free

finish but the seam is

not closed just overlapped. Since this is to the inside and

against the other seat I do not believe that it will ever

be noticed.

This shows the overlapped seams from

the back. Each little wrinkle must be pulled

further and tacked. The tighter

it is the fewer wrinkles.

The side of the seat back is tacked under the seat

bottom.

Note triangular piece cut from edge to make it fit.

The finished job has

received many compliments especially about the seat tops being

square and not sloped down at the front edge. Below – same car but

different light shows the color closer to correct..

Ttalk.info

MGTF Seat Recovering

by John Crawley

The

indents show how the stuffing has failed. It can not be reused

The

indents show how the stuffing has failed. It can not be reused

Glue both the vinyl back and the seat frame with spray glue.

Glue both the vinyl back and the seat frame with spray glue. A thin felt is glued under the vinyl on the bottom side of the seat frame

A thin felt is glued under the vinyl on the bottom side of the seat frame

The

finished bottom part of the seat frame.

The

finished bottom part of the seat frame.

![]() The

piece that was trimmed to make the wooden platform fit is shoved

under the edge

of the wood to add a little extra under the leg support.

The

piece that was trimmed to make the wooden platform fit is shoved

under the edge

of the wood to add a little extra under the leg support.

The

finished cushion . . . If you have wrinkles just pull it tighter

around the bottom. Remove tacks and re-pull if you have to. When it is perfect, hammer the

tacks home.

The

finished cushion . . . If you have wrinkles just pull it tighter

around the bottom. Remove tacks and re-pull if you have to. When it is perfect, hammer the

tacks home.

Fill

is pressed between the sides of the seat back. You can see that

the original felt

and horse hair was

usable. The top of the foam is squared off using extra fiber

fill

Fill

is pressed between the sides of the seat back. You can see that

the original felt

and horse hair was

usable. The top of the foam is squared off using extra fiber

fill

![]() The

seat back seam must be cut from the bottom up to this point to

allow the center

portion to pull under the seat back. At this point I then

machine sewed the seam to

prevent it from pulling out further but this can be done by

hand.

The

seat back seam must be cut from the bottom up to this point to

allow the center

portion to pull under the seat back. At this point I then

machine sewed the seam to

prevent it from pulling out further but this can be done by

hand.

Moss’s

only instruction was to locate the top of the Dog Leg in the

correct spot and start there

when positioning the back cover. It works. Start tacking If you

get wrinkles along the top just pull the leather tighter.

Remember that bruit force is not what you want. work the leather

with the palm of your hand to warm and shape it into place do

not drive the4 tacks home

until you ar 100% satisfied. I left the seat back overnight

several time to allow it to stretch into shape. Align the

vertical narrow panels of the

back with the narrow panels

of the seat bottom.

Moss’s

only instruction was to locate the top of the Dog Leg in the

correct spot and start there

when positioning the back cover. It works. Start tacking If you

get wrinkles along the top just pull the leather tighter.

Remember that bruit force is not what you want. work the leather

with the palm of your hand to warm and shape it into place do

not drive the4 tacks home

until you ar 100% satisfied. I left the seat back overnight

several time to allow it to stretch into shape. Align the

vertical narrow panels of the

back with the narrow panels

of the seat bottom.

![]()

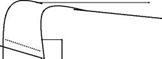

![]() My rather crude drawing of how the

horizontal side seam is cut and then overlapped

on the under piece. The dotted

line shows the seam that I replicated by hand. Much

care is required to do this but it can be done.

My rather crude drawing of how the

horizontal side seam is cut and then overlapped

on the under piece. The dotted

line shows the seam that I replicated by hand. Much

care is required to do this but it can be done.